- About Us

- Solutions/products

- ELV Solutions

- Fire & Safety

- Instrumentation

- Medical

- Renewable Power Solutions

- Telecom Solutions

- Our Clients

- News & Events

- Careers

- Contact Us

Intrinsic safety barriers from Pepperl+Fuchs limit the energy that is supplied to a circuit and protect hazardous areas from excess energy. By limiting energy to a safe level, intrinsically safe circuits prevent the ignition of potentially explosive atmospheres. This simplifies maintenance and repair of Ex i circuits. Different type of Isolated & Zener Barriers.

Intrinsic safety barriers from Pepperl+Fuchs limit the energy that is supplied to a circuit and protect hazardous areas from excess energy. By limiting energy to a safe level, intrinsically safe circuits prevent the ignition of potentially explosive atmospheres. This simplifies maintenance and repair of Ex i circuits. Different type of Isolated & Zener Barriers.

Industrial vision is one of the key sensor technologies of the future. The sensors and systems available from Pepperl+Fuchs range from vision sensors to system solutions that are customized according to the needs of your specific application. From the rack fine positioning of automated storage and retrieval systems to sheet verification in print post-processing, Pepperl+Fuchs offers vision sensors that are designed for your specific applications. Light section sensors based on unique SmartRunner technology enable rugged solutions for reliable presence, completeness, and position detection, even for low-contrast objects and in a wide range of lighting conditions.

Data Sheet

Industrial applications require a high degree of flexibility and an equally low susceptibility to errors—

whether in machine and plant construction, conveyor technology or the packaging industry.

The flexibly combinable 2-D vision sensors of the VOS series provide fast and reliable measurement results,

enabling precise quality control and inspection. The universal sensors are suitable for a wide range of

applications that usually require a complex vision system:

Data Sheet

Based on the proven laser light section method, SmartRunner technology employs a laser line and a camera to

precisely detect height profiles using the triangulation principle. The advantages of the laser light section

method over typical vision sensors are especially clear in difficult ambient conditions. No external lighting is

required, even with low-contrast objects such as metal on metal and single-color plastics. Even different

surfaces, different colors, and extraneous light do not influence the measurement result.

Data Sheet

Pepperl+Fuchs utilizes different technologies to provide industrial positioning systems for virtually any optical positioning task.

Our product range of camera-based positioning systems includes:

Data Sheet

Optical identification systems from Pepperl+Fuchs make an important contribution to key criteria in automation technology, like maximum process reliability and plant availability.

Whether in production or logistics, these systems adapt quickly to application environments and ensure reliable performance even under critical conditions.

Our optical identification portfolio includes a wide range of stationary readers and handhelds. Supporting all common 1-D and 2-D codes, we also provide solutions for high-speed and high-temperature applications.

The operating software “Vision Configurator” enables quick configuration of numerous parameters, allowing you to fine-tune device settings with just a few clicks.

Data Sheet

The event camera (IP65 / -30°C to +50°C) continuously records the last 60 seconds of the video stream.

It provides a 24/7 live view of your application and features an internal ring buffer to capture video recordings 60 seconds before and after a trigger event.

Digital hardware input allows for simple integration into event recording workflows, enabling improved error analysis.

Full HMI integration is made possible through REST API support.

Data Sheet

Vision sensors support fast and easy monitoring of defined sheets in incorrect sheet detection applications. In the printing industry, these sheet verification sensors are used in folding, collating, and binding machines.

A unique feature is the combination of two functions in one sensor: sequences can be monitored through image comparison or by reading barcodes printed on sheets.

The BIS510 and VOS412-BIS vision sensors offer this dual capability, enabling real-time detection of incorrect, faulty, or misaligned printed sheets during production. These sensors perform both printed image comparison and barcode reading—including 1-D codes in vertical and horizontal orientations, and optional Data Matrix codes.

Data Sheet

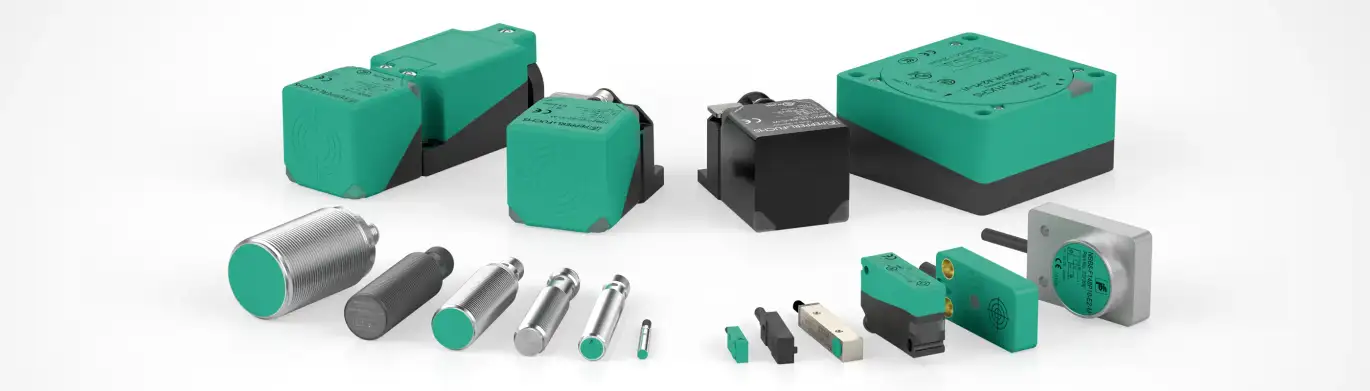

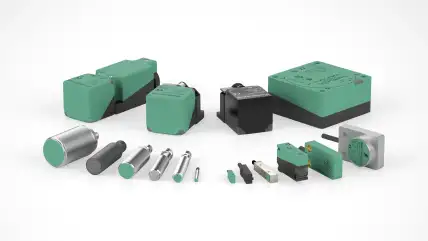

As the inventor of the proximity sensor, Pepperl+Fuchs has continued to further develop and perfect its noncontact, wear-free technology. Having the most experience in the market and a complete portfolio of inductive, capacitive, and magnetic sensors always enables the perfect sensor solution for any application. Using test criteria far beyond the normative requirements, Pepperl+Fuchs sets standards in terms of performance and durability.

Application-specific housing designs, different operating principles, special materials, adapted evaluation electronics, optimized connection technology—all these are characteristics of an individual sensor solution. Pepperl+Fuchs also offers countless sensor customization possibilities for an individual and technically perfect solution in the field of proximity sensors.

Pepperl+Fuchs provides an extensive range of inductive proximity sensors, delivering versatile application possibilities for various industries.

Featuring an array of housing designs, diverse materials, and numerous output signals, these sensors come with global certifications and cutting-edge technologies.

A selection of more than 6,000 sensors offers unparalleled flexibility when it comes to choosing the optimum sensor solution.

The portfolio encompasses both cylindrical and cube-style standard inductive sensors, along with highly specialized sensors that meet every challenge and operate effectively in any environmental condition.

Data Sheet

Capacitive proximity sensors are the perfect solution for detecting nonmetallic objects and substances.

Whether for liquids, granules, paper, or wood, they reliably monitor the fill level in production processes.

Special versions from Pepperl+Fuchs such as rugged sensors in stainless steel or chemically resistant housing materials

guarantee outstanding reliability and service life.

Data Sheet

Where the technology of inductive sensors reaches its limits, magnetic field sensors are a highly versatile alternative.

They can reliably detect magnetic fields through non-magnetizable materials.

Pepperl+Fuchs’ magnetic field sensor selection includes cylindrical styles for traditional applications,

as well as non-contact piston detection sensors for use with steel hydraulic cylinders.

These sensors offer reliable piston magnet detection and can be mounted without the need for slots or holes in the cylinder.

Data Sheet

Perfectly coordinated connectivity and mounting accessories make optimal sensor integration possible.

The comprehensive range of accessories from Pepperl+Fuchs offers the components necessary for ready-to-install solutions.

Data Sheet